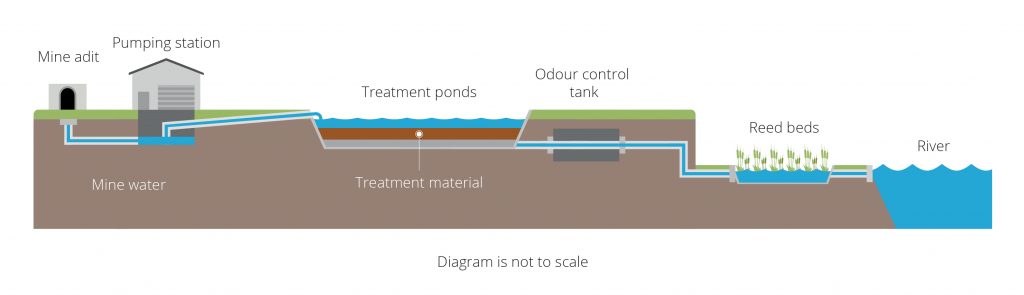

How the treatment scheme works: a nature based solution

The key stages in the Nent Haggs mine water treatment scheme are set out below.

1. Mine water containing high concentrations of zinc and cadmium is put into a pipe as it leaves the mine via the drainage tunnel (also known as an ‘adit’), flows by gravity to the Horse and Wagon field from where it is pumped through a pipe to the treatment ponds.

2. The treatment ponds contain a layer of natural materials: limestone gravel, straw and wood bark. Natural bacterial reactions take place in this layer which remove the metals from the water and capture the metals as solids.

3. These natural reactions generate small amounts of hydrogen sulphide which could cause an unpleasant eggy smell if not controlled. We will prevent any odour nuisance by adding a small amount of hydrogen peroxide to the treated water which will stop the release of hydrogen sulphide.

4. The treated mine water is then passed through aerobic reedbeds for a final ‘polish’. The reeds used at Nent Haggs are Common Reed (Phragmites Australis).

5. The treated water is then returned to the River Nent.

Diagram above shows the process of the Nent Haggs mine water treatment scheme

Odour control system

We have installed systems to destroy hydrogen sulphide before it can cause an odour nuisance. When operational we will add hydrogen peroxide to the effluent in buried tanks next to the treatment ponds since this is the most common method used by industry worldwide. We know that dosing with hydrogen peroxide will work to reduce odours from the site, and that the operational risks, including transport, delivery, storage and use, can be managed safely. This is already done at several Mining Remediation Authority mine water treatment schemes.