Mining History

There has been mining activity in the Midlothian area for hundreds of years, as the coal seams were at surface level and coal could be collected without the need to invest in expensive infrastructure. As time has passed and the surface coal has been depleted, larger shafts were sunk to get to the deeper coal.

The Midlothian area of Scotland was home to 26 colliery sites in the mid-1950s, employing around 11,000 miners. It was the fourth most important coalfield in Scotland after Fife, Lanarkshire and Ayrshire.

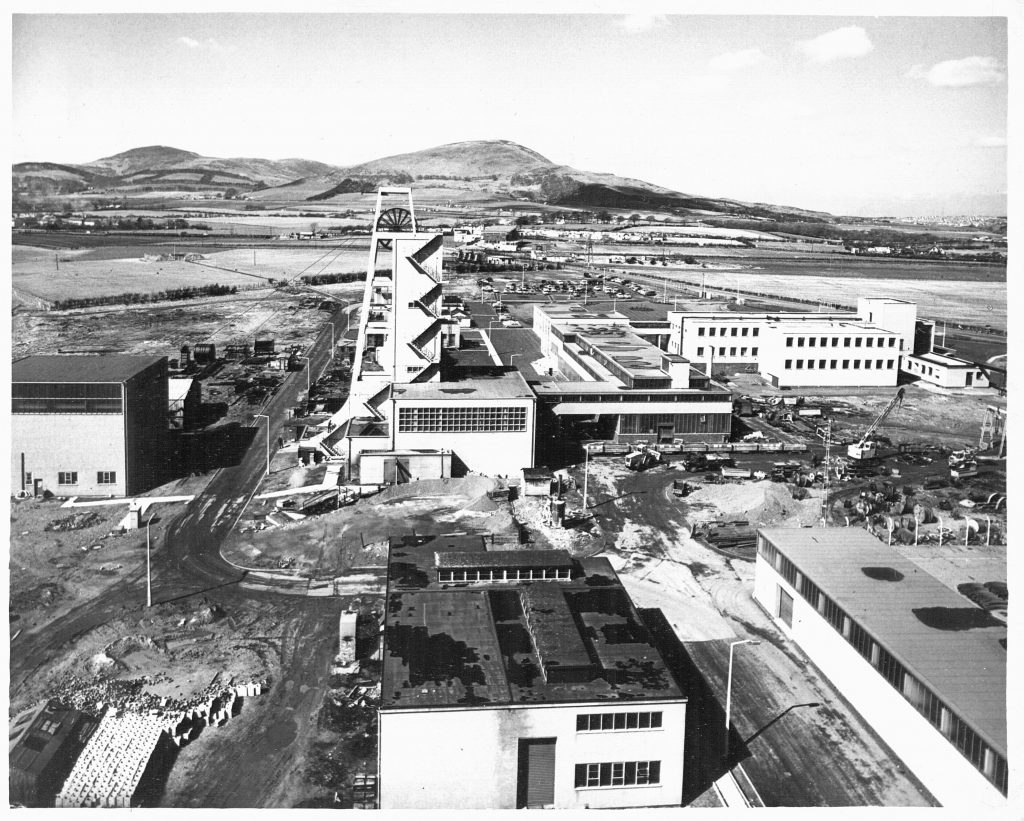

Bilston Glen Winding Tower, September 1955

In the 1950s, the newly formed National Coal Board decided to construct a new “super pit” in the area and selected Bilston near Dalkeith as the site for the new colliery. As a “super pit”, it was expected that the mine would produce over 1 million tons (not tonnes as this was not a UK unit of measurement at the time) of coal per annum.

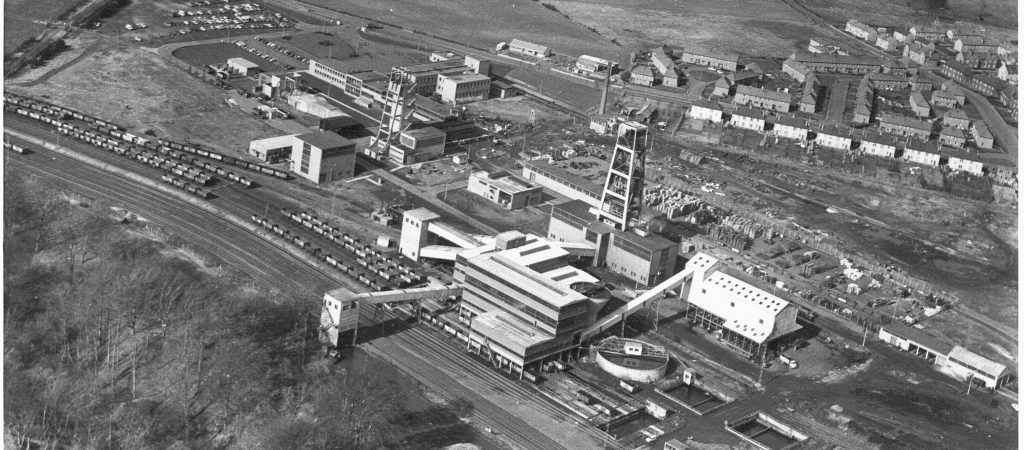

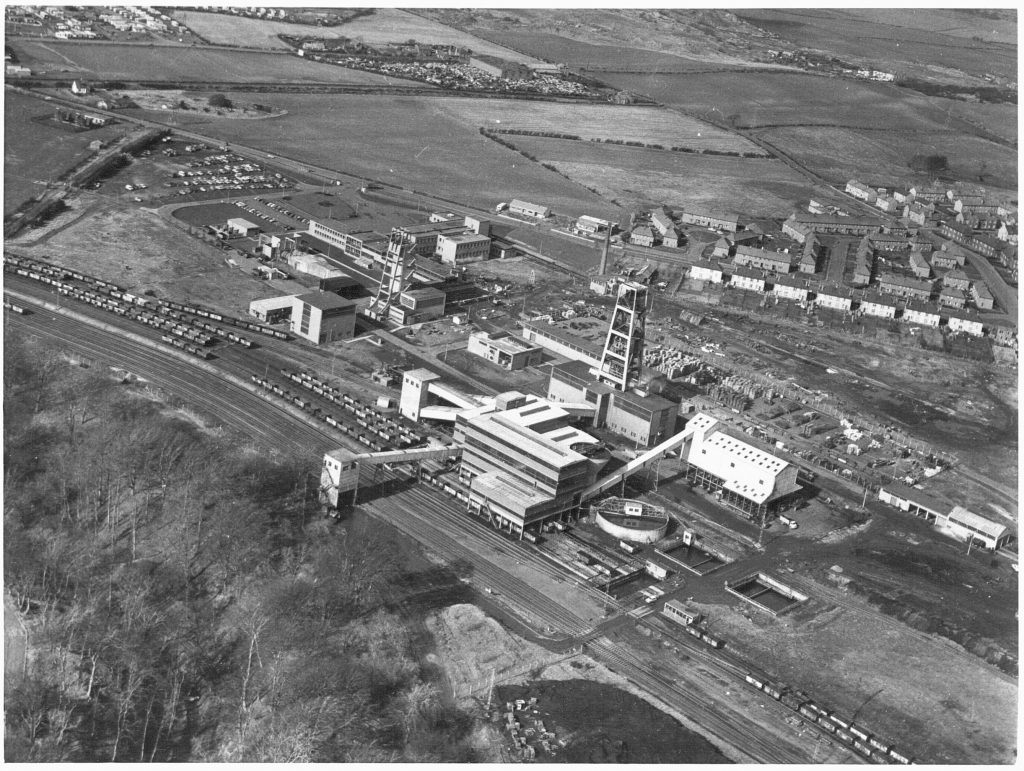

Aerial view of the headgear at Bilston Glen

The Bilston Glen colliery began producing coal in 1954 and continued to do so until its closure in 1989, with over 2300 miners employed at the collieries peak in the 1970s. The colliery was designed to mine deeper into the Midlothian coalfield than other neighbouring collieries and the main shaft extending 750m below ground level. The roadways and working underground connected to existing working to allow air flow and access to undeveloped coal seams.

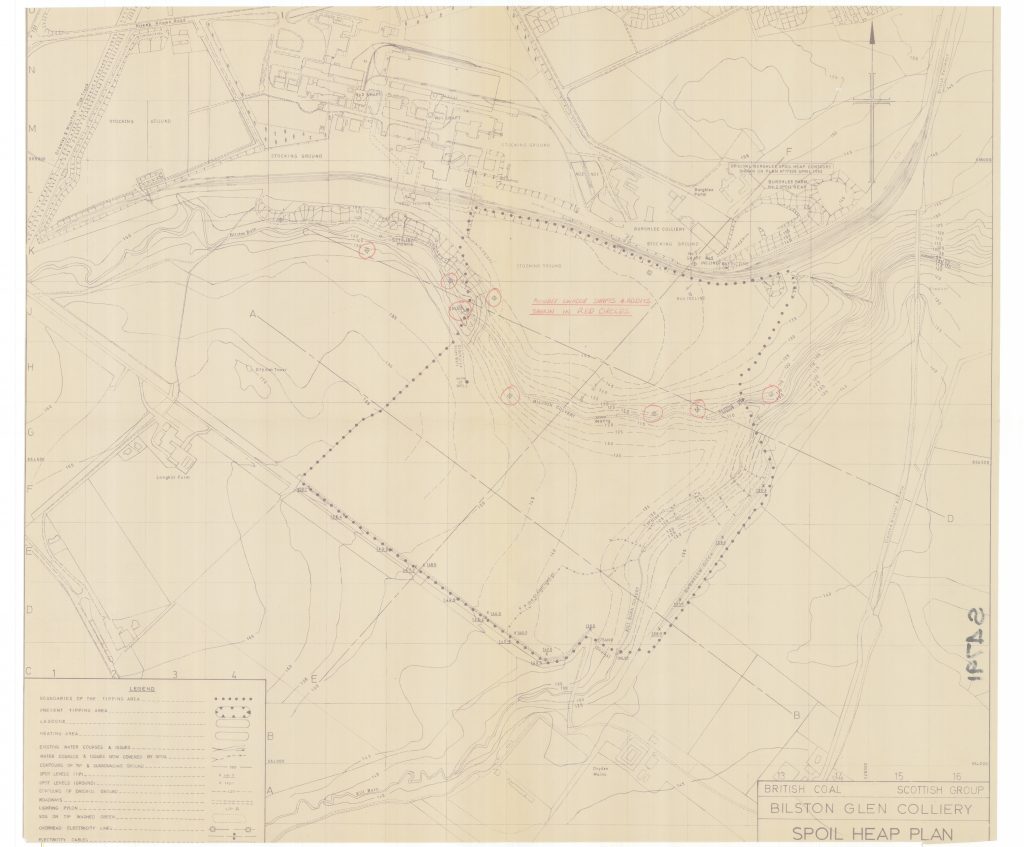

Bilston Glen Spoil Heap Plan

To keep the mine dry water and workable, water that percolated into the workings was pumped out and simply drained via drainage adits/levels into local watercourses.