What Will We Do?

Where possible, the WAMM Programme prefers to use “passive” technologies which do not require continual supervision by people and have minimal input of chemicals or energy since these systems tend to have the lowest whole lifecycle costs. The design of the treatment schemes is determined by the concentrations of metals and how much mine water needs to be treated. We commissioned international mine water treatment experts to identify the best available potential technologies to remove the metals from the mine water before it enters the river.

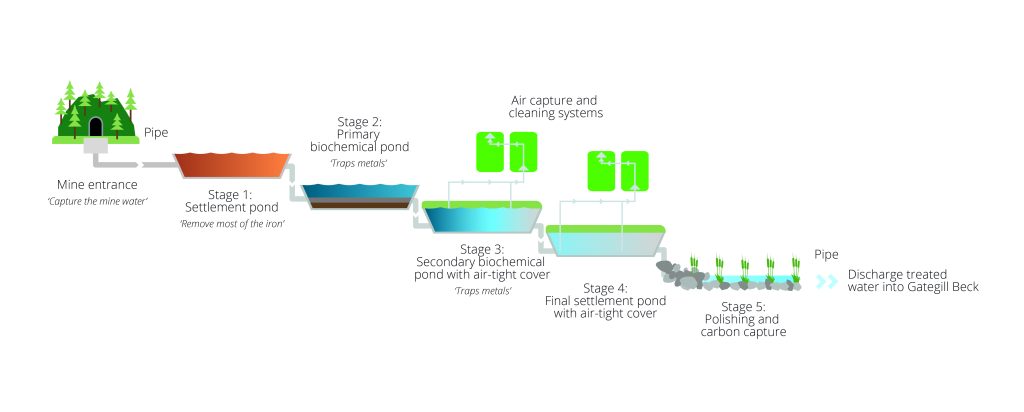

The proposed treatment scheme uses a series of ponds in which the metals are removed by encouraging naturally occurring geochemical, microbiological and ecological processes to occur within natural materials placed in the base of lined treatment ponds. Some of the sulphate present in the mine water is converted into dissolved sulphide which binds to the metals to form solids that are retained in the treatment layer. We expect that more than 90% of the metals will be removed by the treatment scheme.

The very high metal concentrations, acidic pH and the elevated iron in the mine water mean that the proposed Threlkeld mine water treatment scheme has some extra stages when compared to other WAMM schemes such as at Force Crag and Nent Haggs.

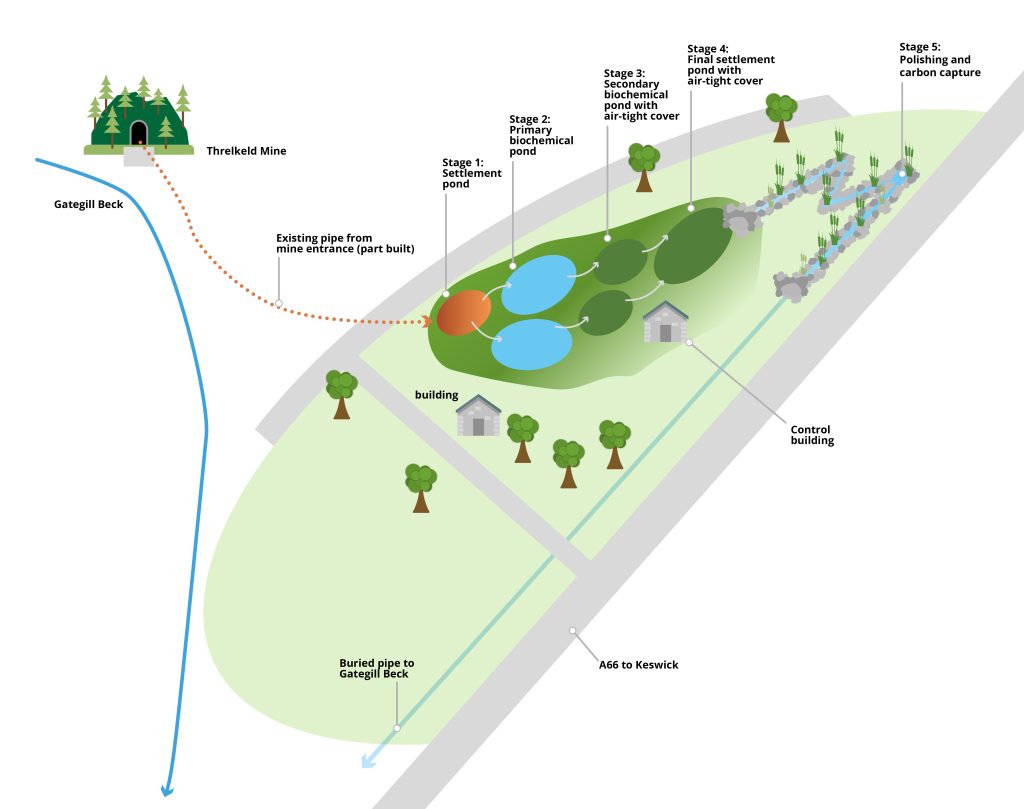

Figure 1 illustrates the key stages of the proposed design. Each stage is described in more detail below.

Mine water transfer: we will capture all of the mine water at the Woodend Low Level, take it to the treatment scheme in a buried pipe, and then return it to Gategill Beck after the metals have been removed.

Treatment scheme:

Stage 1: Settlement Pond

The main purpose of this pond is to remove most of the iron to avoid it clogging up the treatment system. This pond is likely to be orange in colour as the ‘ochre’ – iron oxides – form solids that collect in the pond.

Stage 2: Primary biochemical pond

This open-water pond will raise the pH and begin to remove the target metals: cadmium and zinc. It will contain a layer of natural organic material like compost, woodchips and limestone gravel in which naturally occurring bacterial reactions will encourage the capture of metals. The mine water flows downwards through the layer and out of the base in pipes. It is not expected that any odours will be generated from this pond.

Stage 3: Secondary biochemical pond

This is where most of the metal pollution will be removed from the mine water. It will also contain a layer of natural organic material like compost, woodchips and limestone gravel. The mine water will flow up through this layer.

It is possible that small amounts of hydrogen sulphide gas could be released from the surface of this pond and so an air-tight cover will be installed to capture any potential odours. The captured air will be passed through an air cleaning system (involving activated carbon air filters or similar) to prevent any odour nuisance. This technology is well established worldwide as an effective way to prevent odours.

Stage 4: Final settlement pond

This pond will capture any suspended sediments that leave the biochemical ponds. It is possible that small amounts of hydrogen sulphide gas could be released from the surface of this pond and so an air-tight cover will be installed to capture any potential odours. The captured air will be passed through an air cleaning system.

Stage 5: Wetland cascades

Treated water leaving the final settlement pond may contain low concentrations of dissolved hydrogen sulphide. To prevent any odour nuisance, the water will be aerated and any potential odours removed in an air cleaning system.

The treated water will then pass through a wetland cascade containing reeds which will remove any residual nutrients or sediments before the water is discharged back into Gategill Beck through a buried pipe.